Scientific Program

Thiago Neitzel

University of Campinas, Brazil

Biography:

Thiago Neitzel is a chemical engineer specialist in bioengineering, essentially in alcoholic fermentations, enzymatic hydrolysis and enzyme production aimed at second-generation bioethanol production. He has studied chemical engineering at Åbo Akademi in Finland through the Brazilian Exchange Programme, Science without Borders. Currently at the third year of the PhD program in bioenergy at the State University of Campinas (UNICAMP), a multi-institutional program of the University of São Paulo (USP) in partnership with the São Paulo State University (UNESP) and UNICAMP developing his doctoral project in the Brazilian Bioethanol Science and Technology Laboratory (CTBE) located in the National Center for Research in Energy and Materials (CNPEM) in Campinas – São Paulo.

Abstract

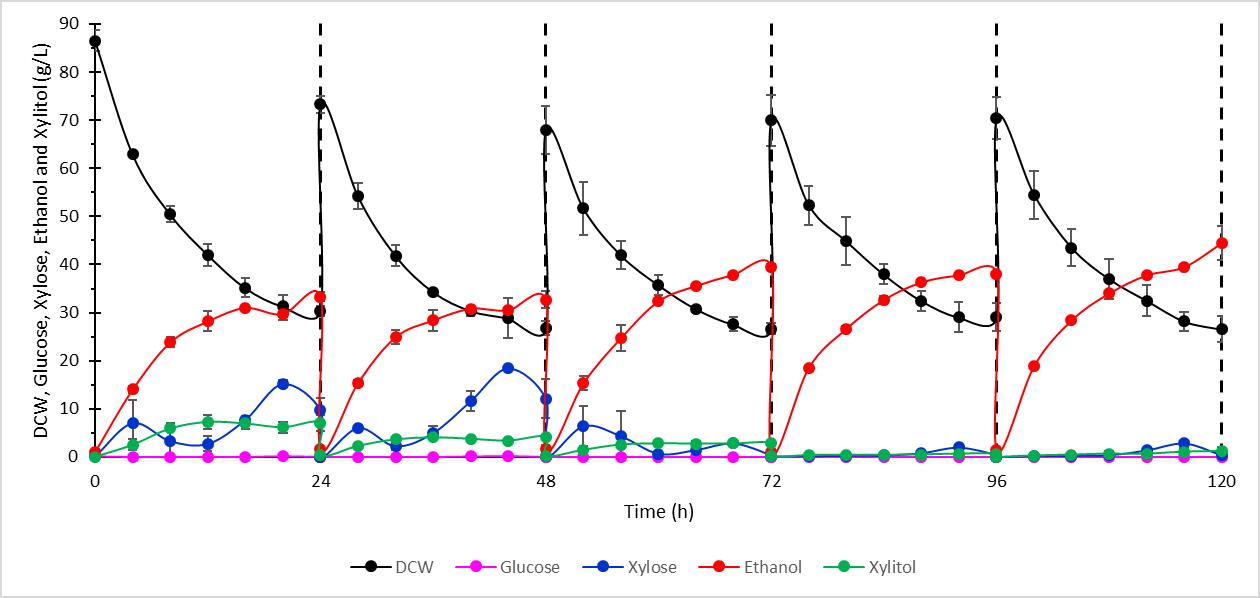

Lignocellulosic biomass is a vast and important renewable resource with potential to replace a sizable share of the global demand for fossil fuels, especially in Brazil because of sugarcane high productivity and consolidated bioenergy system1. Hence, both sugarcane bagasse and straw are lignocellulosic feedstocks available for conversion into biofuels and biochemicals. However, it is necessary to submit this biomass into pretreatment and hydrolysis steps to get fermentable sugars1.The focus of this project is to apply the stablished Melle-Boinot fermentation process, used on first-generation bioethanol production for second generation bioethanol process, coupled with the novel wild yeast Spathaspora passalidarum NRRL Y-27907 which is reported capable of naturally ferment xylose faster than glucose or using both carbohydrates,3,4. Five fed-batch fermentation cycles of 24 h and 90 gL-1 of sugars were performed with the fixed temperature of 30 ºC (70 % of xylose and 30 % of glucose). As showed on Image 1, an adaptation effect through the cycles was observed with an increase from the first to the last cycle of 1.3 times in ethanol productivity (1.34 and 1.68 g.L-1h-1), 22 % in ethanol yield (77.20 and 91.16 %), 9.9 % in xylose consumption (84.02 % and 99.41 %) and 11.2 g/L in bioethanol concentration (29.95 g.L-1 and 41.55 g.L-1). Therefore, the strategy increases bioethanol production, being a useful tool and applicable in second generation process. Bearing in mind the importance of achieved results, RNA-seq and metabolomics will be carried out to comprehend physiologically the benefits of this process.

Figure 1: Fermentation profile with the temperature of each cycle fixed in 30 ºC.

- Advancements in Photonics

- Nano photonics and Bio photonics

- Organic photonics

- Photonic Integrated Circuits

- Microwave Photonics

- Optoelectronics

- Optical physics

- Optical Communications and Networking

- Laser Systems

- Optics and Lasers in Medicine

- Technologies in Lasers, Optics and Photonics

- Bio-inspired photonics

- Applications and Trends in Photonics