Scientific Program

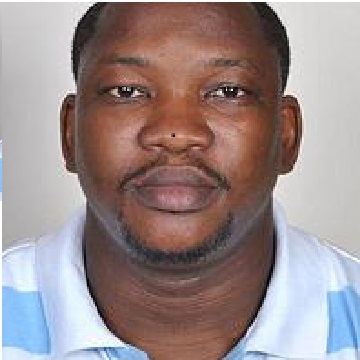

Lukmon Owolabi Afolabi

Universiti Sains Malaysia, Malaysia

Biography:

Lukmon Owolabi Afolabi is currently a faculty member of FKMP / UTHM and previously a postdoctoral research fellow at Universiti Sains Malaysia (USM) and University Technology Petronas (UTP) Malaysia. He obtained his PhD degree from UTP, Malaysia. His research is in areas of sustainable development, renewable energy studies, polymer composites and nanotechnologies. He’s currently working to develop an innovative process techniques on electrospine of coated hollow microspheres crystal structure for lightweight syntactic foams fabrication for engineering applications. He has published papers many reputed journals, conferences and book chapters. His is a guest editor, assistant editor and reviewer of repute. Dr. Lukmon also pursues interests infusing new technology into the energy storage materials for advance thermal transport. He is a chartered engineer and member of Institute of mechanical engineers (MIMechE) UK.

Abstract

This study mainly concerns the role of foam heating process techniques and its impact on cellular micromorphology, density and gas liberation mechanism of natural rubber foam with distilled water as blowing agent. Three different modes of heating process techniques and varying amount of distilled water have been examined on the foam density and cellular morphology, having rather identical morphological formation, cell distribution and relatively reducing densities but significant cell wall thickness. It is deduced that the increase in the water loading substantially affects the decrease in the foam densities, cell uniformity and stability. However, the heating process techniques influence the cell distribution and stability more than the amount of water content loading. The combine microwave oven process technique has improved the process of moisture diffusion into the water-blown open cell natural rubber foam unlike the slower procedure of conventional heating technique. In addition, the natural rubber foam physical properties and microstructure is improved better than the conventional heating technique. In all the simultaneous combine microwave oven technique is the best among the evaluated technique for the experiment because of density increment, cell distribution, pores flaccidity and uniform cells.

- Advanced Materials and Functional Devices

- Engineering Materials & Composite Materials

- Magnetic and Multiferroic Materials

- Advanced Optical and Magnetic Materials

- Advanced Bio-Materials & Bio-Devices

- Cluster Science and Nano-Toxicology

- Energy Materials and Harvesting

- Advancement in Nanomaterials Science and Nanotechnology

- Nano Materials & Their Properties

- Carbon Nanostructures and Graphene

- Nano Medicine & Drug Delivery

- Nanotechnology in Water Treatment